Having solar charging capabilities on the trailer was one of my main goals to bring the Mini-Me Stress into the 21st century. A composting toilet was the other, but that's another blog...

In getting this goal accomplished want to thanks the folks at AM Solar in Springfield, Oregon. They spent a lot of time on the phone holding my hand and guiding me through the design and installation process. Greg, Dave and Roger, you guys rock! Could not be any nicer or more knowledgeable. Their website:

http://amsolar.com has a lot of great information and videos.

On the internets (as G.W. would say...) You Tube's LoveYourRV channel has great info. It was through that channel that I was introduced to Bob from HandyBob Solar, whose advice I followed closely.

https://handybobsolar.wordpress.com/.

There is so much information out there about solar systems for RVs that it can be overwhelming and confusing. After endless research here is what I chose:

Batteries:

Two Trojan T145 6-volt deep-cycle flooded batteries, connected in series. Check out my "Tongue work" blog for a photo. I chose Trojan because of the great reviews, proven history and they are an American company.

http://www.trojanbattery.com. I picked the T145 model because they have the highest amp hours for that size Trojan battery (260 amp hour rating). I went with flooded cell because it is proven technology and maintenance is not a big deal, just a few minutes every month or so.

Bought mine just down the street from United Battery

http://unitedbattery.net, here in Portland. Good price and the folks there could not be any nicer or more customer friendly. I have also bought my car batteries there and highly recommend them.

Solar charge controller:

You can go crazy reading about MPPT vs PWM controllers and bla, bla, bla...Forget about it. I just went with what Handy Bob said and got the Bogart Engineering SC-2030 PWM solar charge controller. Designed to work with my battery monitor, great reviews, American made and great customer support. Called Bogart a couple of times on some minor installation questions and immediately got an answer. Their website

http://www.bogartengineering.com is full of good information. I bought the controller through AM Solar.

The most important feature of my Bogart battery monitor/solar charge controller system is the ability to program the solar controller to charge the Trojan batteries up to 14.8 amps. This is what Trojan recommends and this no converter on the market (certainly not my Intellli-power noisy converter) can do. Only through solar can you get these batteries fully charged! Handy Bob rants about this over and over and I finally got it. This was the number one reason I chose this controller.

Controller location:

As close to the batteries as I could get and still have the controller inside the trailer. Bob says "very important!" and I a Belieber. Less than 24 inches of heavy wire from the controller to the battery.

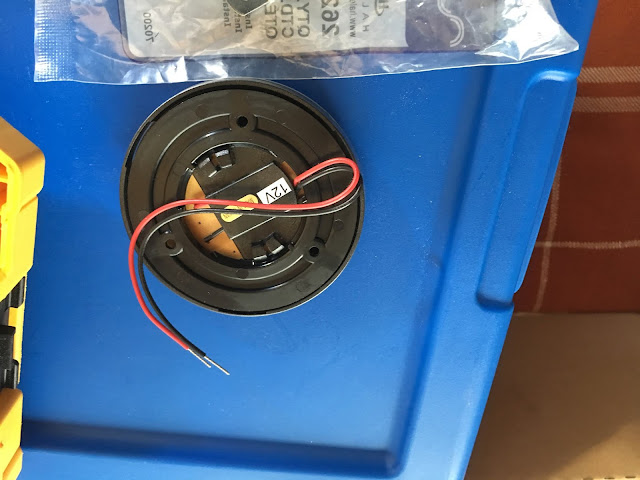

Here is the solar controller with its dedicated circuit breaker. I also have each solar panel fused so the controller is protected on both sides.

Wiring:

Handy Bob says "go big" and I did. I have 6-gauge wire running from my solar panel combiner area to the controller, 6-gauge from the controller to my positive and negative bus bars and 2-gauge from the bus bars to the battery terminals. I planned the wire runs to minimize distance between components. Some people will tell you that using such heavy wire is overkill, just read what Bob says. If Bob says it, I can dig it...

I ran my solar panel wires in through the fridge vent:

From there into the front of the rear closet where the individual panel wires are combined and head to the controller on 6-gauge wire. A lot of RV solar systems use a "combiner box" (basically a glorified weatherproof bus bar) up on the roof to make the panel wire connections. I had good access to the fridge vent area because the upper cabinet had been removed to be refinished so I just made the connections inside the trailer using bus bars. Better access and don't have to worry about weatherproofing the connections. You can see how each solar panel has its own in-line fuse:

In my readings I found that technically you only have to fuse individual panels when your array has more than two panels, but as usual I believe more is better when it comes to fuses. Plus the fuses allows me to isolate each panel individually if I need to. As mentioned in a previous blog I also installed an on/off switch between the positive solar panel bus bar and the solar charge controller so I can isolate the array from the rest of the electrical system

Solar panels:

Poly vs mono, bla, bla, bla...The more you read about this the more you realize it does not matter. Just get the panels that fit your power and footprint needs. Period. I looked for a local solar panel dealer and found LightHarvest Solar:

http://www.lightharvestsolar.com/12-volt-battery-kits.html. The owner is Miles, who could not be any nicer. I needed to maximize the small roof footprint I had and they offered a 40 x 40 inch Solar Cynergy 140-watt panel that fit my needs. So I got two panels and they cover just about all my roof.

Here is the rear panel getting ready to be installed in its new home:

Panel power requirements:

While researching how stupid to get with the solar panel footprint, in other words how many and how big a panel array I needed, I found the answer to be: "It depends". It all depends on your usage.

You can get an approximate idea of your usage by adding up the manufacturers' specified amperage use of the equipment you are planning to install. My LED lights draw very little amperage and go a long way towards reducing amp hour usage as compared to incandescent. Add the water pump, fans and other draws. There is also the matter of how big an inverter, and other electronic gizmos, I might decide to install in the future. I wanted to stay flexible. Since my biggest limitation was the amount of roof space available, I chose to install the largest panels I could fit on the roof and back into my amp hour charging capacity.

My two 140-watt panels got me to 280 watts of solar panel energy for the system. How does this translate to the batteries I chose and how charged up I can keep them? Well, I took a couple of the rule of thumb array size formulas out there to give me a ballpark idea. One formula says: Match the amp hours of your batteries with the watts on the array. Two 140 watt panels is 280 watts, pretty close to the 260 amp hours on the battery. Check. Other formula says: Take 3 percent of your amp hours (260 time .03) equals 7.8 and this is the amount of amps you need out of each panel. These particular panels are rated to produce 8 amps per peak sun hour each, so again the math says this should work. Check. Of course this is all assuming good sunlight, inflated specs and what not.

Panel installation:

Although I bought the panels locally, I ordered AM Solar's rocker foot mount kits. These allow for the panels to be tilted for winter when the sun is lower on the horizon and also make it easier to clean under the panels. I was impressed with the quality of the parts and AM Solar includes everything you need in the kit to get the job finished.

AM Solar recommends attaching the panels to the metal roof with just the 3M two-sided tape that they provide. I spoke to Greg from AM Solar and he assured me that the tape is adequate for the job. They have installed thousands of panels this way and not one has come loose. I a chicken so I used the tape and then I also screwed the feet to the roof...Greg clearly is not familiar with my ability to generate never-before-seen events...

Here is the front panel installed:

Notice how the rear panel, which you can just barely start to see on the lower left of the photo, sits away from the vent fan cover. When the vent is open no part of the panel will be shaded. The front panel is close to the vent because the cover hinges on the front so even when fully open it will not shade that panel. Very important not to have shade on your panels. I say this and yet the whole trailer is in the shade...hmmmm....

AM Solar sells a panel tilting kit but it is designed for their panels which are smaller than the ones I have so their tilt bars are too short for my application. I ordered two extra sets of their mount knobs and fabricated my own tilt bars:

The wires are secured to the roof using Alumibond tape which is UV resistant and also makes for a cleaner installation. All the connectors are shrink wrapped and weatherproof. There is enough slack on the panel wiring to allow for tilting to either side of the trailer.

She may be 51 years old, but she tech savvy!...